Wire Harness Manufacturing Process

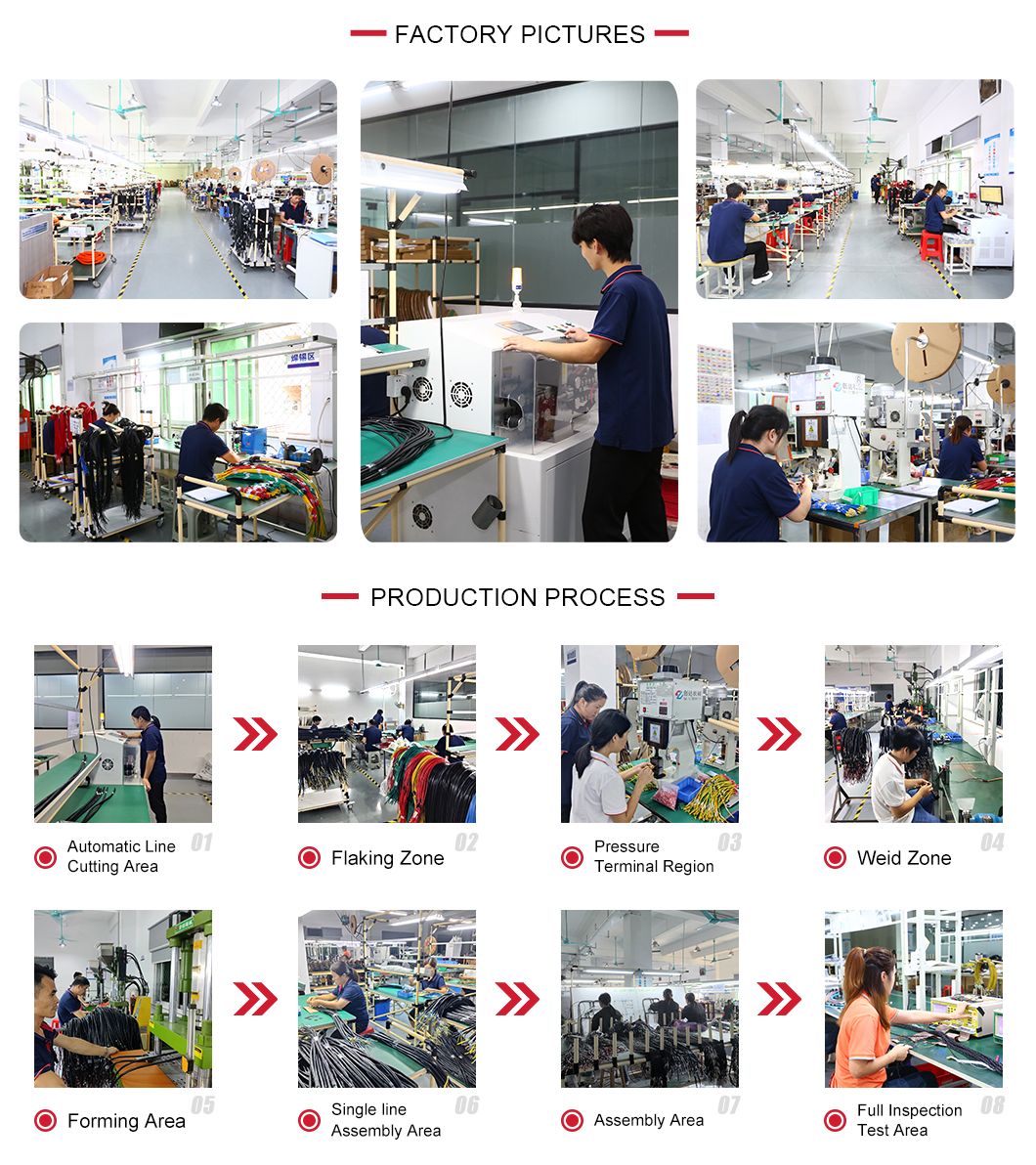

Wire processing: This includes processes such as wire cutting, stripping, and crimping terminals. According to design requirements, the wire is cut to the appropriate length; a wire stripper removes the insulation from both ends of the wire; and a crimper securely crimps the terminals onto the wire to form a wire assembly.

Assembly: The wire assembly is assembled with connectors, protective covers, and cable ties. According to the Wiring Harness drawing, wire assemblies of different specifications are inserted into the corresponding connector holes. Protective covers are used to protect key areas, and cable ties and clips are used to secure the wiring harness. Welding: Welding is used for complex connections or areas requiring higher reliability. For example, in sensor wiring harnesses, some wires must be connected to the circuit board by soldering.

Wire harness forming: The assembled wire harness is formed using molds or manual methods to conform to the required shape and size for installation.

Sejow is a custom manufacturer of precision CNC Machining Parts and wire harness.We can provide OEM/ODM wiring harness ,CNC machining parts based on your requirements. Wiring harness, also known as Cable Harness, for industrial ,automotive,new energy and medical equipment .CNC machining parts are assembly of Cnc Milling Service which transmit signals or electrical power. In the future, Sejow will continue to uphold the business philosophy of "integrity, responsibility, and innovation", provide customers with better products and services, and work together to create a better tomorrow.